This is what product developers and manufacturers dream about.

Quite often, those materials are polymers – wondrous, ubiquitous substances forged from chemically bonded molecules. Make polymers better, faster and cheaper, and you create a real competitive advantage for your product.

But it’s not easy. Improving polymers requires rigorous formulation: The recipe is tweaked again and again for a better result. This trial-and-error approach that can take years, and it requires lots of money.

Matmerize changes that paradigm in a big way.

Launched out of the Georgia Tech lab of GRA Eminent Scholar Rampi Ramprasad, Matmerize offers a polymer informatics software platform (PolymRizeTM) that uses machine learning to vastly reduce the costly guesswork in R&D experiments on polymer formulations.

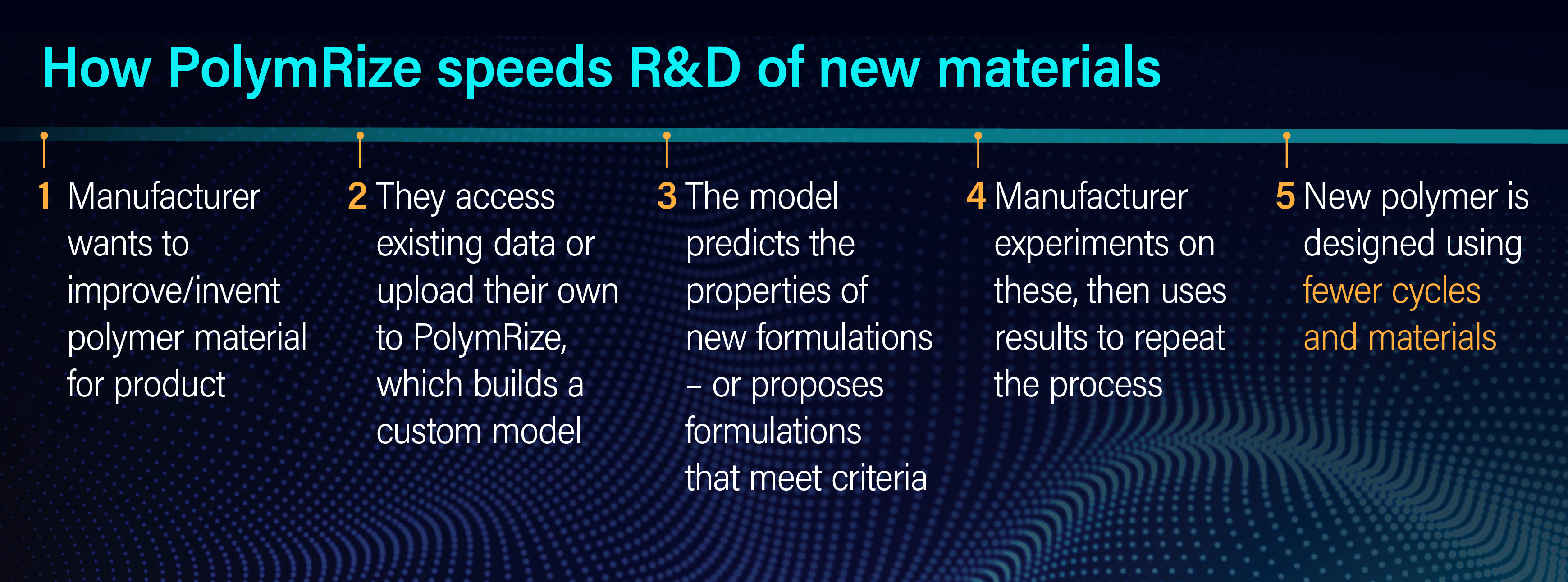

Built into PolymRize are vast amounts of data and polymer formulation design algorithms.

Client R&D teams use this data to create models – powered by machine learning – that predict the properties of a newly designed polymer.

After identifying the models that look most promising, R&D teams then create the actual polymer in the lab and evaluate it. Most likely, it’s not quite there yet – but the data from those experiments informs the next iteration of models and expected results.

The predictions generated by the machine-learning software add precision and speed to lab development. If the journey to develop a new polymer were a car ride, PolymRize is like putting a foot all the way down on the gas and keeping it there.

And that’s only the half of it.

Beyond accessing Matmerize’s ever-growing data repository on polymers, the makers of products can upload their own proprietary data on polymer formulations they’ve been working on to create the “custom” predictive models just for them.

Matmerize never sees this data – for security purposes, it disappears once the model is created – and the R&D team gets instant results on how likely a new formulation will perform as desired.

“There’s also a third capability, and that’s design,” Ramprasad says. “The client can say, for example, ‘I need a formulation that has particular values for properties X and Y.’ They specify the desired property values, and the PolymRize algorithm actually shows which formulations will meet or nearly meet their criteria – and which won’t.”

The technology and approach for Matmerize evolved out of an earlier polymer-building platform developed by Ramprasad. Called Polymer Genome, it allows users to “build” their own polymer – by drawing the polymer, using its SMILES strings (molecular structure) or searching for it by name.

“Polymer Genome is an academic product that’s provided free of charge,” Ramprasad points out, “but it doesn’t offer privacy or security, and the user has to upload information for one polymer at a time. And users can’t build models with their own datasets.”

By contrast, the new PolymRize platform enables clients to upload specifications for an unlimited number of formulations all at once – and provides predictions for new formulations in seconds. The Polymer Genome academic platform also lacks the robust screening capabilities of PolymRize.

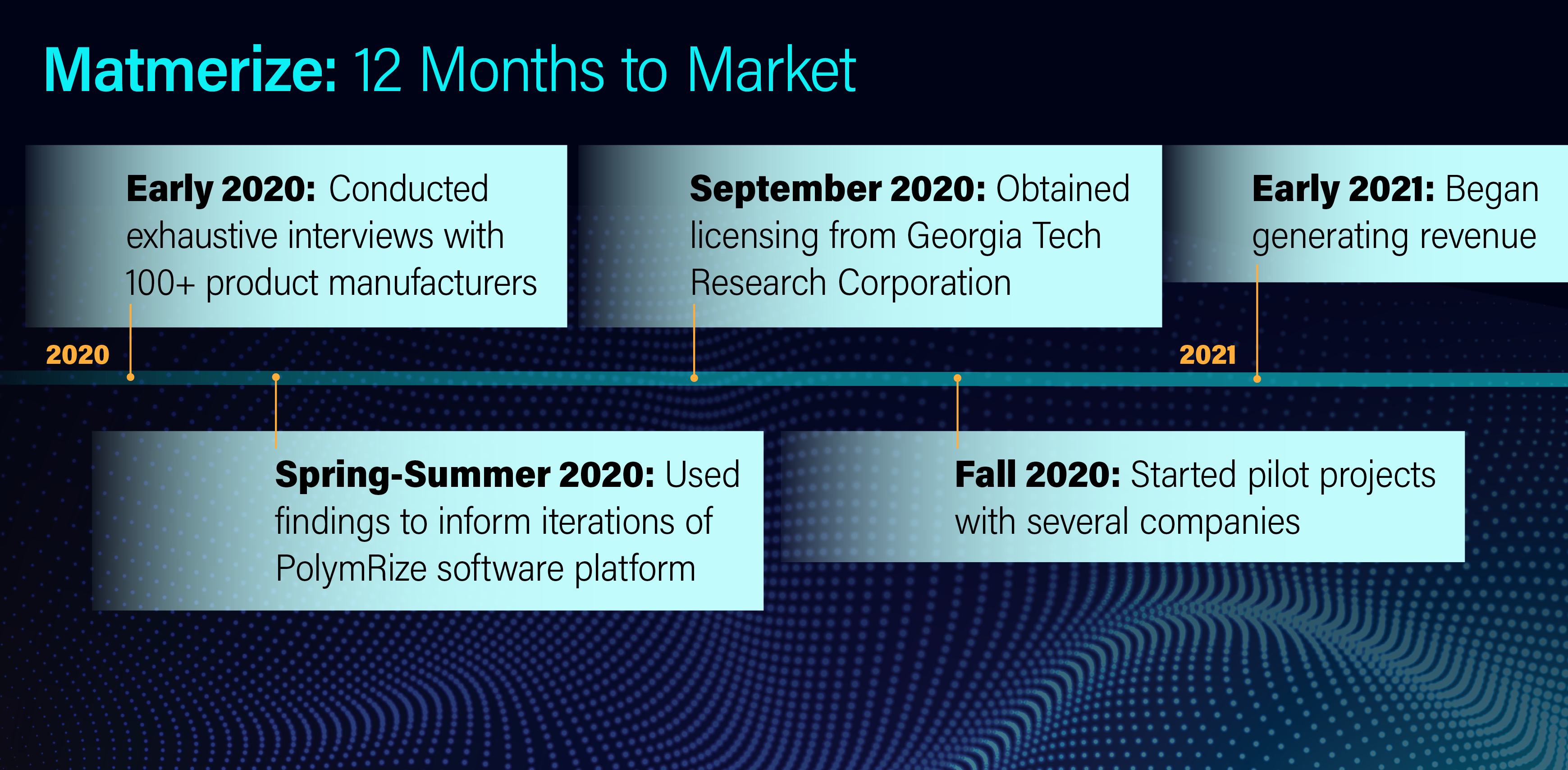

The emergence of Matmerize is a story that resembles the speed embedded in the company’s value proposition.

When GRA and Georgia Tech recruited Ramprasad to Georgia Tech from the University of Connecticut in 2018, they brought one of the world’s leading pioneers of using quantum mechanics and machine learning to develop new materials.

Joining Ramprasad in his move to Georgia was Chiho Kim, a colleague in his lab, and the two co-founded Matmerize. GRA made one of the first investments in the company, and in just a short time, the company started generating revenue.

“The Ramprasad Lab and Georgia Tech VentureLab have some extremely skillful people who could modify the software very quickly,” says Jon Goldman, entrepreneur-in-residence for GRA and a principal at Georgia Tech VentureLab. “They were able to address requests for features in just a few weeks, and the team understood how to build software that’s robust, rugged and scalable.”

When he arrived in Georgia, Ramprasad also brought with him a major research project already underway: A U.S. Department of Defense initiative to develop polymers that improve how capacitors store energy.

Since then, the Ramprasad Lab has landed another DoD project – this time to reduce the amount of plastics in our world. They’re working to develop new classes of polymers that are both structurally sound and recyclable on-demand. Advances in this area would help inform plastics that break down after use, for example.

“The challenge is designing materials that are both strong and recyclable or biodegradable, attributes that generally conflict with each other,” Ramprasad says.

To that end, the machine learning-powered PolymRize platform will be a huge benefit, not only to Ramprasad’s work but the efforts of manufacturers of plastics.

“Already, we have a client that’s started a pilot project for developing products that utilize new kinds of recyclable, biodegradable polymers,” he says.

Stronger but sustainable plastics would be transformative to the world. Likewise, the invention of other new materials will improve humankind in many ways. Those days are in the future; with Matmerize, they’ll arrive much sooner.

“We had a lot of support getting Matmerize off the ground and into the marketplace so quickly,” Ramprasad says. “I’m especially appreciative of Georgia Tech’s School of Materials Science and Engineering, plus GTRC and VentureLab. And GRA played a pivotal role with right-time, early-stage investment and advice."