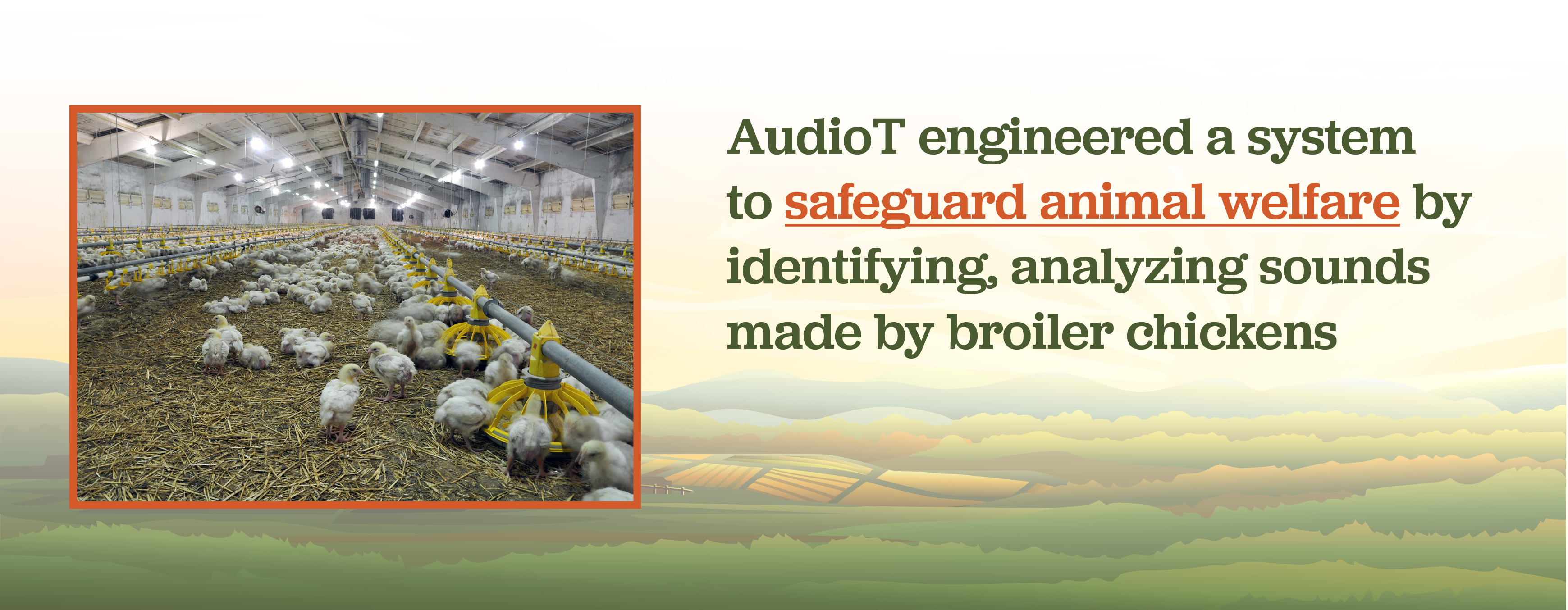

Even a trained eye can’t discern all that’s happening inside a poultry grow-out house, home to tens of thousands of broiler chickens. The birds bob-walk about, pecking food from dispensers and buck-buck-bucking in conversation. Everything looks as you’d expect.

But there’s nuance to the peeps, chirps, clucks and other sounds chickens make. And nuance invites questions. Are the new arrival chickens having trouble adjusting to lighting? Is part of the flock feeling depressed? Are those scratchy coughs a sign of a serious virus – or just a little dust in the gullet?

Technology developed at Georgia Tech help answers these and many other questions that have a bearing on poultry health. Now being evaluated under the startup AudioT, the technology monitors vocalized sounds from chickens and translates them into a clearer picture of what’s really going on inside the grow-out house.

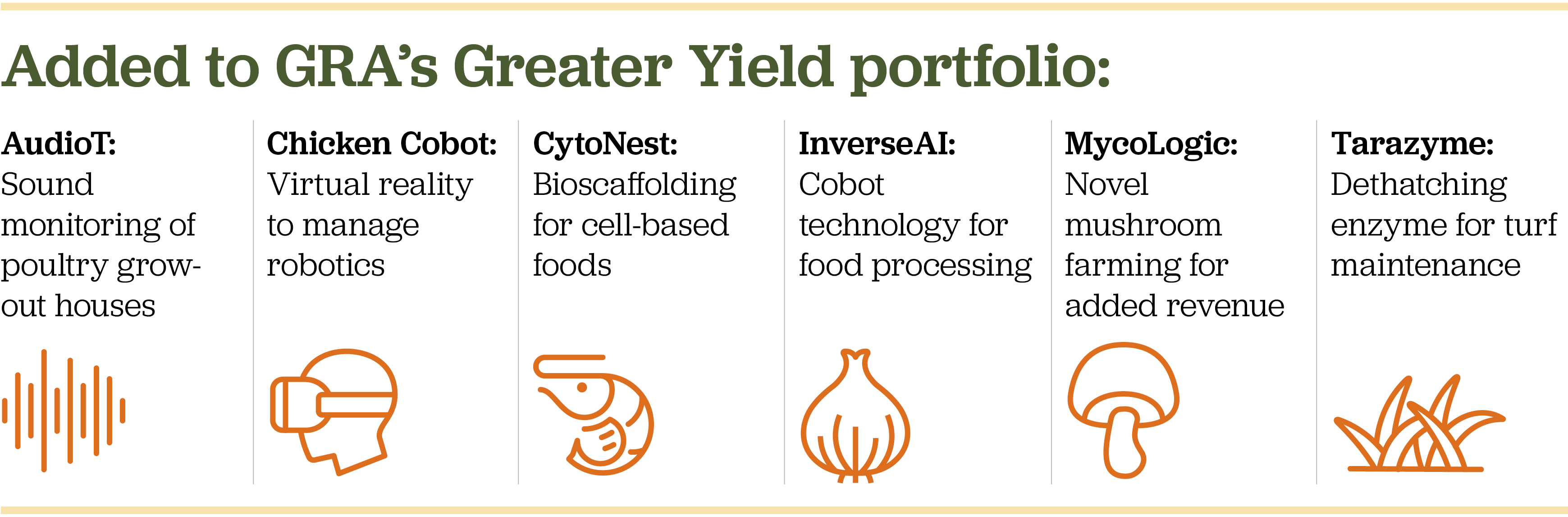

AudioT is one of several startups receiving early investment and advice from GRA’s venture development program as part of the Alliance’s Greater Yield initiative. The initiative aims to find and nurture more inventions in Georgia’s university labs and deliver them to Georgia’s farms and food producers.

In the case of AudioT, the implications are enormous. Broiler chickens are the nation’s top source of animal protein, and Georgia grows 15 percent of all broilers in the U.S. – more than any other state. Safeguarding the health and well-being of the animals is a moral imperative, not to mention an economic necessity.

“The goals of our system are to provide a total picture of bird welfare based on expressed behaviors, including comfort, nutrition and emotional state,” says Tom Darbonne, CEO of AudioT. “Think of it as collecting and analyzing evidence of bird welfare.”

That evidence, Darbonne adds, should help farmers make adjustments in the grow-out house environment to optimize the growth and protection of chickens. AudioT collects it by placing microphones in zones throughout the house for continuous monitoring, then using computers to identify “auditory shapes” that correlate with previously recorded sounds and associated outcomes. Machine learning guides computers to recognize and respond to patterns, thus creating an association between the birds’ sounds and their welfare, both positive and negative.

“For example, when birds are introduced in the house as chickens, they’ve come from a stressful hatch and transport process, and a predominant call is a stress call,” Darbonne explains. “If they’re having trouble acclimating, they won’t eat or drink enough, which can depress their immune system for the rest of their lives. Our system identifies, counts and analyzes these stress calls as well as other sounds.”

AudioT got a major boost from industry when the Foundation for Food & Agriculture Research named it one of six companies in 2020 to receive funding from FFAR’s Smart Broiler research initiative. A $200,000 grant was matched by McDonald’s corporation, and Tyson Foods and Fieldale Farms added in-kind contributions. The award was renewed in 2022 for $300,000 for the second phase of the program.

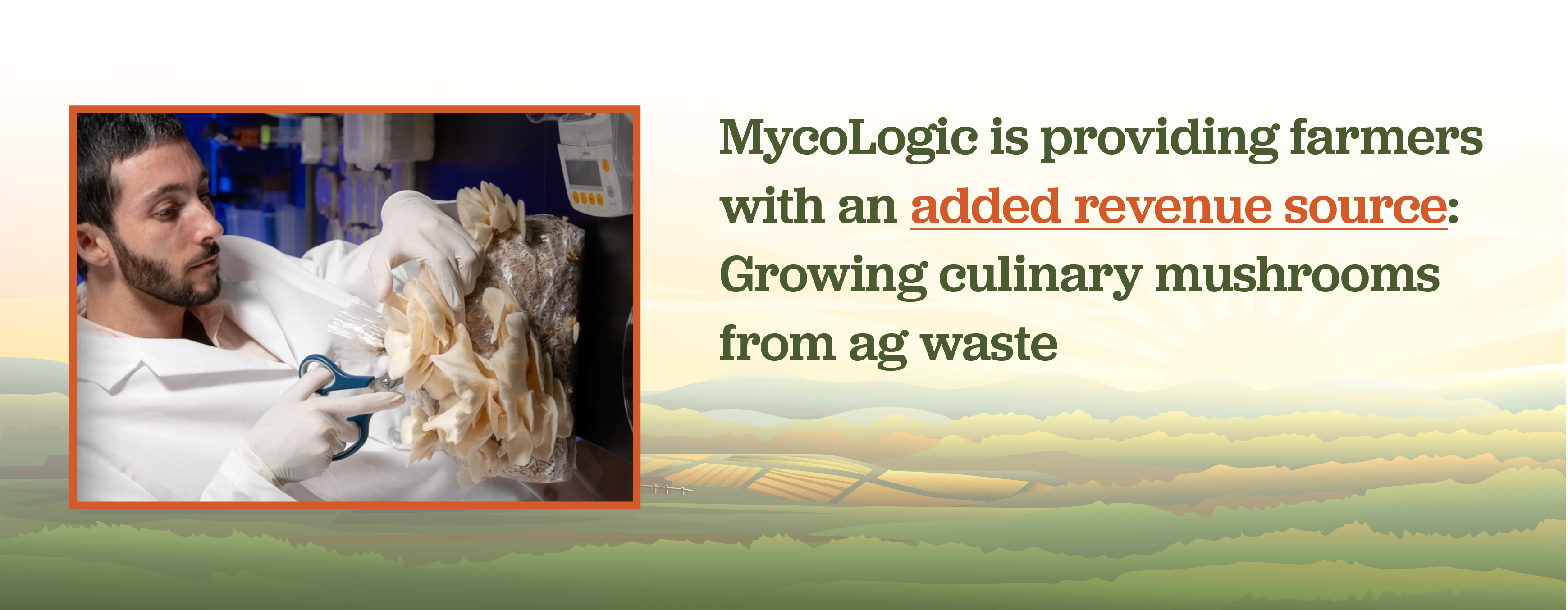

Inside an altogether different environment – in this case, a 40-foot shipping container – another agricultural wonder is unfolding, thanks to the invention of Georgia universities.

Here, a cluster of devices, wires and sensors allows Georgia farmers to add a valuable crop to their repertoire: mushrooms.

The container is itself a farm, one that uses highly sensitized technology to create an optimal environment for growing shiitake, oyster and other culinary mushrooms. Researchers at Kennesaw State University devised and engineered the system, which is now being piloted by MycoLogic, a startup supported by GRA’s Greater Yield Initiative.

“These containers represent an opportunity for farmers in Georgia and elsewhere to generate substantial additional revenue,” says Chris Cornelison, assistant professor of microbiology at KSU and co-founder of MycoLogic. “Mushrooms have become very popular, and a recent survey from USDA showed that most mushroom growers can’t keep up with demand.” Currently, the majority of edible mushrooms in the U.S. come from a single county in Pennsylvania.

MycoLogic’s system is more than a climate-controlled container. Hygienically prepared bags of agricultural waste – cotton gin trash, peanut shells, spent brewing grains – sit on racks and become substrates after microscopic fungi are introduced and later multiply. Once the ag waste is permeated with fungi, the bag is punctured, and mushrooms begin to grow outside of it.

All of this happens under carefully calibrated and monitored conditions of temperature and humidity, and MycoLogic is using machine learning to refine the system’s software (Mycodo) over time. While mushroom farming is a do-it-yourself endeavor, the company plans to serve as consultant and guide for customers who need it. MycoLogic is also exploring whether to develop a facility to create the substrates for those who want them.

Tests of MycoLogic’s second-generation system in fall 2022 produced record yields of mushrooms. The company will complete its pilot program early in 2023 and go to market with an offering to help farmers “grow more mushrooms, better.”

And like AudioT, MycoLogic caught the eye of industry in late 2022: It was named as one of just 10 semi-finalist teams to compete in the 2023 Farm Bureau Ag Innovation Challenge, an event carrying a $50,000 top prize. MycoLogic will make its pitch Jan. 6 in San Juan, Puerto Rico.

Beyond AudioT and MycoLogic, GRA is working to bring several other technologies from Georgia universities to Georgia farms.

UGA-launched InverseAI creates technology in the space where humans and robots collaborate to increase productivity and accuracy in produce processing. The company’s technology uses high-res cameras and laser range finders to meticulously observe human performance of tasks, then uses that data to improve the performance of robots. The resulting technology, embodied in collaborative robots called cobots, have been demonstrated in the sorting of Vidalia onions at UGA’s Vidalia Onion and Vegetable Research Center in Lyons, Ga.

CytoNest (also out of UGA) uses nanofiber technology to grow shrimp and meat from cultured cells. CytoNest doesn’t provide the cells – it creates the 3D scaffolds the cells need to grow. Made from food-compatible material, the company’s scaffolds allow for nutrients and metabolites to be exchanged continuously and efficiently. This capability overcomes some of the limitations posed by other commercial-grade systems on the market. The CytoNest technology could provide a solution to an expected worldwide shortage of dietary protein in the coming decades.

PoultryE is complementary to AudioT — instead of audio, it uses sophisticated imaging and phenotyping technology to monitor broiler chickens. Developed at UGA, the technology monitors and analyzes the behavior of broiler chickens in grow-out houses. It also tracks pecking behavior and egg laying by hens in cage-free houses. PoultryE's technology is guided by machine learning.

Georgia Tech researchers have developed a tech platform that uses augmented and virtual reality (VR) technology to control a robotic arm in poultry processing. Picture wearing a VR headset, like an Oculus Rift, and being able to see and control an actual robotic arm to perform repeated, menial tasks on the poultry assembly line. While still in development, the technology uses highly sensitive cameras and sensors to marry robotics with virtual reality. Its use in poultry processing not only addresses a critical labor shortage — it also improves worker safety.

UGA-launched Tarazyme has an enzyme that helps remove thatch from the turf of golf courses and athletic fields. Such turf needs frequent aeration, but thatch is a big impediment in the process. It’s a loose, organic material that builds up and prevents water from penetrating deep enough to hydrate the grass. Tarazyme’s enzyme blends copper with oxidase to break down thatch without harming turf – saving venues enormous amounts of time and money without temporarily closing golf courses for thatch removal.

Scientists at UGA are engineering transgenic alfalfa to better withstand drought conditions. A popular crop for feeding animals, “forage alfalfa” is often grown in areas that are increasingly threatened by drought. The engineering project at UGA is expected to help extend growing seasons, increase planting on less-than-optimal sites and improve the quality of the alfalfa.

X-Cot is developing technology to increase the yield of high-quality cotton. UGA research into chemically induced mutations in cotton genes revealed some that significantly improve fibers without affecting yield. X-Cot is replicating trials of modifying cotton in spring 2023. The improved cotton would command higher prices for seed companies, higher prices for farmers and better-quality garments for consumers.

MycoMelanin is using fungi as a new source for producing eumelanin, a class of pigments that’s increasingly being used in products, particularly in electronics and medicine. The most sought-after class of melanin, eumelanin is sourced mostly from cuttlefish. However, limited supply and increasing use are driving demand for new sources. MycoMelanin, out of Kennesaw State, has identified mushroom-bearing fungi as source for producing eumelanin in cell cultures.

Ground Control Robotics is a Georgia Tech-launched company developing a robot that can remove weeds in varied terrains. To inform development of the robots, the company is using data from studies of how different physical and robotic systems navigate terrains. A decline in agricultural manpower and the rise of weeds that resist herbicides are creating demand for new solutions. Robots may be the answer.

Farmers facing the prospect of throwing away produce can instead call Retaaza. The startup sources surpluses of local produce and sells it to corporate buyers. The service model reduces food waste and benefits the environment. Retaaza is working on a project with Georgia Tech to help it evaluate the environmental effects of its business model.